Production unit

The production capacity is 100 tons / day and it is provided by the most modern equipment, purchased from world-renowned suppliers, through personal investments and through the SAPARD program developed by the European Union. There are 18 product categories, which include the entire range of deli meats on the consumer market. For each product group there is a certain manufacturing technology that takes place in certain stages such as: cutting, preparation, heat treatments in specialized cells for microbiological safety, cooling, and then storage of the finished product.

Packing and thermoforming hall

After the production process is completed, all products are transported from production to this unit. Here, the operations of portioning, slicing, packaging / thermoforming are performed, using the appropriate method for each type of product. Storage is customized, by categories. Everything is done automatically, with state-of-the-art machines, which ensure packaging in conditions of maximum hygiene and safety. There is also a separate portioning and slicing room, in order to avoid cross-contamination.

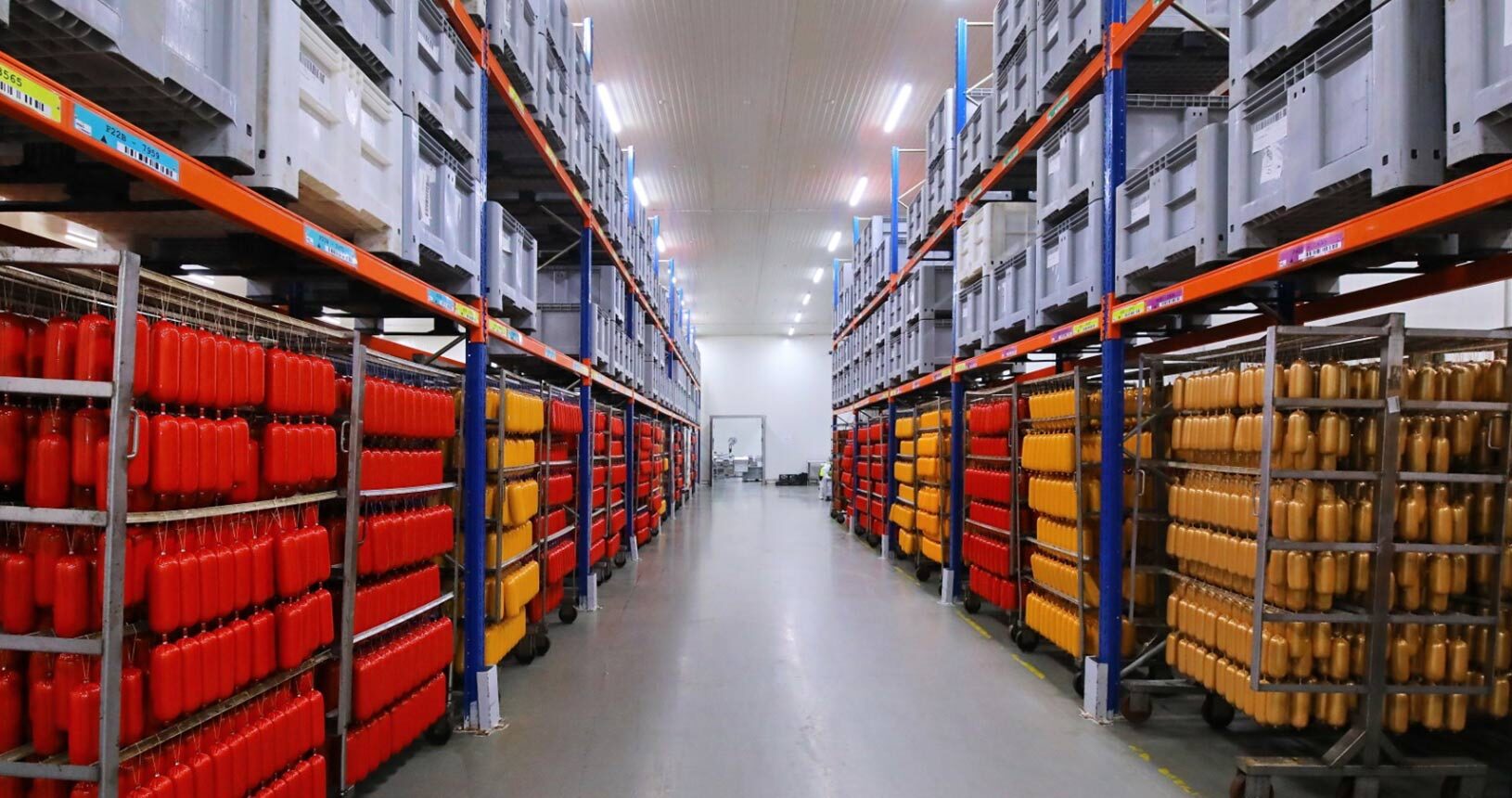

Raw-dried maturation hall

Here the semi-finished products are received, in accordance with sanitary veterinary conditions, and are subjected to a long maturation process. The raw-dried products are carefully monitored, the registration of the parameters being done in a computer system throughout the maturation process. At the end, the products are checked. All maturation cells are sanitized according to internal procedures.

Logistic storage

All packaged products arrive in this hall, where the goods are prepared for delivery. There are two automatic packing / forming lines for the bulks. The products are packed in the secondary packaging and then placed on pallets. Here, a state-of-the-art robot places the bulks on pallets with maximum precision, after which they are wrapped in plastic foil. This storage unit has a capacity of 500 tons.

Slaughterhouse

The slaughterhouse is a modern unit with a cutting room, as well as ancillary spaces for the separate storage of pig and bovine / sheep carcasses, edible by-products, as well as for inedible products. Since January 2012, the slaughterhouse has been veterinary certified and has received approval for the slaughter and marketing of fresh meat of pigs, cattle and sheep.

Frozen storage

Our factory has two freezer warehouses, which ensure the necessary raw material for a reasonable period of time. They have a capacity of 400 and 580 tons, respectively.

Laboratory

For the health of our consumers,in order to ensure the quality of our products, and to put on the market products that are physically and chemically compliant, our company has set up its own factory laboratory, equipped with state-of-the-art equipment. The laboratory is sanitary-veterinary authorized to determine the following physicochemical parameters: humidity, salt and nitrites. In addition, by using the modern SCANFOOD equipment, the following parameters are physicochemically tested: fat, saturated fatty acids, protein, collagen, collagen / protein ratio, carbohydrates, ash, nutritional values (Kj, Kcal) and water activity. The device gives us real-time results, as the time required to perform an analysis is a maximum of 1 minute.

Ripening, slicing and packaging hall

It has an area of 1094 m2, a raw-dry ripening capacity of 29 tons/week and a slicing and packing capacity of 5 tons/day. The value of the investment amounts to 3.5 million euros.

The department is equipped with state-of-the-art machines in the field of sliced products. To prevent cross-contamination, the slicing line is separated from the packaging line, thus respecting all safety criteria. The slicing and packing line is approximately 23 m long, equipped with a metal detector and ultraviolet lamps.

In order to offer you weight-compliant products, the packaging line has integrated a high-performance scale, with the help of which all sliced products are checked individually.

Spice storage

The spice warehouse was built in 2015. The spices are stored in specially arranged spaces, on pallets or shelves, ensuring the necessary spices for a reasonable period of time. The supplies are sourced from the spice warehouse, depending on the daily orders.